NdFeB Flexible Magnets

NdFeB Flexible Magnet is a kind of flexible permanent magnetic materials with high power, whose performance is more excellent than that of the ferrite magnet components, which could be used for various kinds of high powered micro-motors, which could compact the external dimension widely, and improve the motor performance. It is the originate in China.

NdFeB Flexible Magnet is a kind of flexible permanent magnetic materials with high power, whose performance is more excellent than that of the ferrite magnet components, which could be used for various kinds of high powered micro-motors, which could compact the external dimension widely, and improve the motor performance. It is the originate in China.

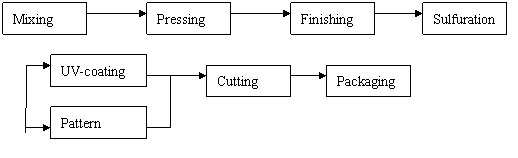

Production Process of NdFeB Flexible Magnets

NdFeB Flexible Magnet is composed by of melt-spun NdFeB powder and rubber.

Thickness: 0.5~8.0 mm

Length: as per your requirement.

Magnetization: multi-poles or through the thickness

Surface treatment: UV coated or Patterned

Characteristics of NdFeB Flexible Magnets

- The strongest isotropic flexible magnet in the world so far, a Max. BH of 90KJ/m3(11.25MGO) is available at laboratory, an amazing 5 times more than that for Ferrite magnetic strip, quite close to the highest property of compression Molded NdFeB ring magnet, magnetic property for industrial batch quantity ranges from 16 to 68 KJ/m3(2.0-8.5MGO).

- Outstanding flexural strength, can be automatically assembled, with an efficiency better than compression molded ring magnet.

- Dispensing with mold, short downtime.

- Applicable temperature: -40℃~120℃;

- After systematic reliability inspection, it is consistent and reliable.

- Can be made into different shapes such as long strip, slim strip, ring, pore plate, large sheeting, etc. to meet different requirements.

Dimension range (mm) of NdFeB Flexible Magnets:

Thickness |

Width |

Length |

0.3~6.0 |

~ 300 |

unconfined |

|

0.4~3.0 |

~ 200 |

~ 300 |

Wide application range of NdFeB Flexible Magnets

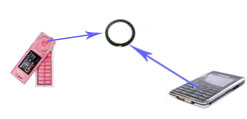

- Sensor

Handy phone,cell phone Wheel key.Applied for mobile phone(wheel key), radio mouse, protector guarding against theft for commodities in supermarket, etc

. - Micro-motor strip

Used for cash register, portable DVD, SERVO FAN, laptop computer, etc.

- Plane loudspeaker

Used for TV, stereo device, etc.

- Strong attraction application

The highest magnetism flexible magnet in the world!

Magnetic Properties of NdFeB Flexible Magnets

FLEXIBLE NdFeB MAGNET |

|||||||||||||

Material Type |

DXN2 |

DXN3 |

DXN4 |

DXN5 |

DXN6 |

DXN7 |

DXN8 |

DXNE2 |

DXNE3 |

DXNE4 |

DXNE5 |

||

Magnetic Properties |

|||||||||||||

Residual Induction(Br) |

kGs |

2.5~3.5 |

3.3~4.3 |

3.8~4.8 |

4.3~5.3 |

4.8~5.8 |

5.3~6.3 |

5.7~6.7 |

2.5~3.5 |

3.5~4.5 |

4.5~5.5 |

5.5~6.5 |

|

Residual Induction(Br) |

T |

0.25~ 0.35 |

0.33~ 0.43 |

0.38~ 0.48 |

0.43~ 0.53 |

0.48~ 0.58 |

0.53~ 0.63 |

0.57~ 0.67 |

0.25~ 0.35 |

0.35~ 0.45 |

0.45~ 0.55 |

0.55~ 0.65 |

|

Coercive force(Hcb) |

kOe |

1.5~2.5 |

2.1~3.1 |

2.7~3.7 |

3.2~4.2 |

3.7~4.7 |

4.3~5.3 |

4.5~5.5 |

1.5~2.5 |

2.1~3.1 |

2.5~3.5 |

2.5~3.5 |

|

Coercive force(Hcb) |

kA/m |

120~200 |

170~250 |

210~300 |

250~340 |

290~380 |

340~420 |

350~440 |

120~200 |

170~250 |

200~280 |

200~280 |

|

Intrinsic coercive force(Hcj) |

kOe |

2.0~4.0 |

4.8~6.8 |

6.8~8.8 |

7.8~9.8 |

8.0~10.0 |

8.5~11.0 |

8.5~11.0 |

2.0~4.0 |

3.5~5.5 |

4.5~5.5 |

4.5~5.5 |

|

Intrinsic coercive force(Hcj) |

kA/m |

150~320 |

380~540 |

540~700 |

620~780 |

630~800 |

670~880 |

670~880 |

150~320 |

280~440 |

350~440 |

350~440 |

|

Max energy product(BH)max |

MGOe |

1.5~2.5 |

2.5~3.5 |

3.5~4.5 |

4.5~5.5 |

5.5~6.5 |

6.5~7.5 |

7.5~8.5 |

1.5~2.5 |

2.5~3.5 |

3.5~4.5 |

4.5~5.5 |

|

Max energy product(BH)max |

kJ/m3 |

12~20 |

20~28 |

28~36 |

36~44 |

44~52 |

52~60 |

60~68 |

12~20 |

20~28 |

28~36 |

36~44 |

|

Temperature Coefficient of Br |

%/℃ |

-0.11 |

-0.11 |

-0.11 |

-0.11 |

-0.11 |

-0.11 |

-0.11 |

-0.16 |

-0.16 |

-0.17 |

-0.17 |

|

Flux Irreversible Loss |

% |

<5 |

<5 |

<5 |

<5 |

<5 |

<5 |

<5 |

<5 |

<5 |

<5 |

<6 |

|

Max Operating Temperature |

℃ |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

100 |

100 |

100 |

100 |

|

Physical Properties |

|||||||||||||

Tensile Strength(MPa) |

>3 |

||||||||||||

Elongation(%) |

30~80 |

||||||||||||

Hardness (Shore D) |

30~80 |

||||||||||||

Density (g/cm³) |

3.30~ 3.90 |

4.00~ 4.60 |

4.40~ 5.00 |

4.65~ 5.25 |

4.65~ 5.25 |

4.80~ 5.40 |

5.10~ 5.70 |

3.45~ 4.05 |

4.10~ 4.70 |

4.50~ 5.10 |

4.90~ 5.50 |

||

Weight reduction by heat(%) |

<1 |

<1 |

<1 |

<1 |

<1 |

<1 |

<1 |

<1 |

<1 |

<1 |

<1 |

||

Reliability |

|||||||||||||

Heat-Resistant (100℃×72h) |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

||

Cold-Resistant (-40℃×72h) |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

*** |

||

Wet-Resistant (60℃×90%RH×72h) |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

||

Hydraulic Oil-Resistant(23℃×72h) |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

||

Cold-Heat Impact-Resistan |

*** |

*** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

||

Salt Water (23℃×5%NaCl×24h) |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

** |

||

Remark: *** Excellent ** Good *Acceptable × Bad

|

|||||||||||||