Magnetic Raw Material

Products: Magnetic Powder | Magnetic Compound

Magnetic Compound

Magnetic compound for magnet strips of door gasket

Magnetic compound for Extruding fridge strip

DXF series of Bonded Ferrite Magnetic compound, including Bonded Barium Ferrite Compound and Bonded Strontium Ferrite Compound are suitable for making various bonded magnets. They have good compatibility with different kinds of composite materials, such as nylon, resin, polyvinyl chloride and rubber etc.. Due to the large particle size, such powders have high filling capacity. They can be used for making different kinds of magnets by extrusion or infecting moulding. The strict quality control system of our plant ensures that the quality is stable and consistent.

DXF series of Bonded Ferrite Magnetic compound, including Bonded Barium Ferrite Compound and Bonded Strontium Ferrite Compound are suitable for making various bonded magnets. They have good compatibility with different kinds of composite materials, such as nylon, resin, polyvinyl chloride and rubber etc.. Due to the large particle size, such powders have high filling capacity. They can be used for making different kinds of magnets by extrusion or infecting moulding. The strict quality control system of our plant ensures that the quality is stable and consistent.

| Type | Magnetic Properties | Moisture (%) | |||||

| Materials | Br (mT) | bHc (kA/m) | iHc (kA/m) | (BH)max (kJ/m3 ) | Testing Method | ||

| DXF-1 | BaFe12O19 | 150¡À10 | 95.5¡À8 | 183¡À16 | 4.0¡À0.4 | Calendering | =0.5 |

| DXF-1b | BaFe12O19 | 160¡À5 | 99.5¡À4 | 199¡À8 | 4.4¡À0.4 | Green piece | =0.5 |

| DXF-2 | BaFe12O19 | 200¡À10 | 127¡À8 | 151¡À8 | 7.2¡À0.4 | Calendering | =0.5 |

| DXF-2b | BaFe12O19 | 200¡À10 | 119¡À4 | 143¡À8 | 6.8¡À0.4 | Calendering | =0.5 |

| DXF-2c | BaFe12O19 | 200¡À10 | 119¡À4 | 143¡À8 | 6.8¡À0.4 | Calendering | =0.5 |

| DXF-2S | SrFe12O19 | 200¡À10 | 127¡À8 | 151¡À16 | 7.1¡À0.4 | Calendering | =0.5 |

| DXF-2Sb | SrFe12O19 | 200¡À10 | 119¡À4 | 143¡À16 | 7.1¡À0.4 | Calendering | =0.5 |

| DXF-2Sc | SrFe12O19 | 200¡À5 | 119¡À4 | 143¡À16 | 7.1¡À0.4 | Calendering | =0.5 |

Test result of magnetic strip used for refrigerator gaskets

Characteristics for extruded strip

(measured on finished extruded strip dim. 2.4 x 9 mm with insulation)

Properties |

|

Values |

|||

| 2.4 x 9 (mm) | 2.4 x 9 (mm) | 2.4 x 9 (mm) | |||

| 1. | Hardness Shore | Hs (A) | 96 | 96.2 | 96.6 |

| 2. | Density | g/cm3 | 3.55 | 3.76 | 3.57 |

| 3. | Force of cohesion (with 0.5mm air gap) |

g/cm | 72.4 | 272.4 | 72.4 |

| 4. | Max. surface magnetic induction | mT | 75 | 71 | 74 |

| 5. | Tear resistance | kg/cm2 | 72 | 76 | 68 |

| 6. | Crack elongation rate | % | 124 | 107 | 87 |

| 7. | Temp. coefficient of surface magnetic force, continuously working for 240 hours at 80 |

% | 1.5 | 0.7 | 0.3 |

| 8. | Temp. coefficient of surface magnetic force, continuously working for 240 hours at -20 |

1.4 | 1.3 | 0.3> | |

| 9. | Flexural strength (twist around a stick |¦Ì 16mm) | Passed | Passed | Passed | |

| 10. | Torsion characteristics: when torsion around 360 | Passed | Passed | Passed | |

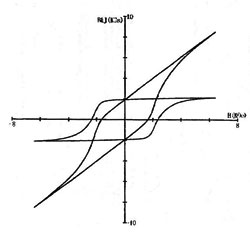

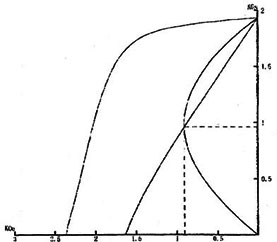

Magnetic properties of magnetic compound

Shape: cylinder

Size: Dia.25.5mm

Test temperature: 21

Material: N13

| Remanence Br |

Coercive Force HcB |

Intrinsic Coercive Force HcJ |

Max. Energy Products (BH)max. |

||||||||

| T | Gs | KA/m | Oe | KA/m | Oe | KJ/m3 | MGOe | ||||

| .1936 | 1936 | 130.3 | 1637 | 187.4 | 2356 | 6.918 | .8693 | ||||

| Bd | Hd | Hm | HK | HK/HcJ | |||||||

| Gs | Oe | Oe | Oe | ||||||||

| 961.0 | 904.8 | 12807 | 1474 | .6255 | |||||||

color of magnetic compound:

White, black, gray, light yellow, light black, porcelain white, etc, anyway, specific hardness, color of PVC compound could be made as per customers's demands.

shape of magnetic compound:

Dimensions and tolerances as well as polarity correspond to the relevant valid XIAMEN DEXING drawing.

storage of magnetic compound:

In general, long storage times in a humid and got climate may results in brittleness of the magnetic strip. The storage time should not exceed: 12 months at a storage temperature of up to 25![]() /50% relative humidity, 6 months at a storage temperature of up to 40

/50% relative humidity, 6 months at a storage temperature of up to 40![]() /50% relative humidity.

/50% relative humidity.

In case of higher temperatures and humidities, the storage time should be reduced accordingly. The cartons should remain sealed during storage in order to avoid possible hardening of the magnetic strip caused by long-term exposure to light. Permissible stacking height for stationary storage: tree pallets on top of each other.

function of magnetic compound:

We guarantee a series delivery according to specification. The customer determines the suitability of our products of the specific application by way of appropriated functional tests of series delivery. For Dexing, the written approval of sampled quality is proof of functionality. Further guarantees are not assumed by Dexing